Table of Contents

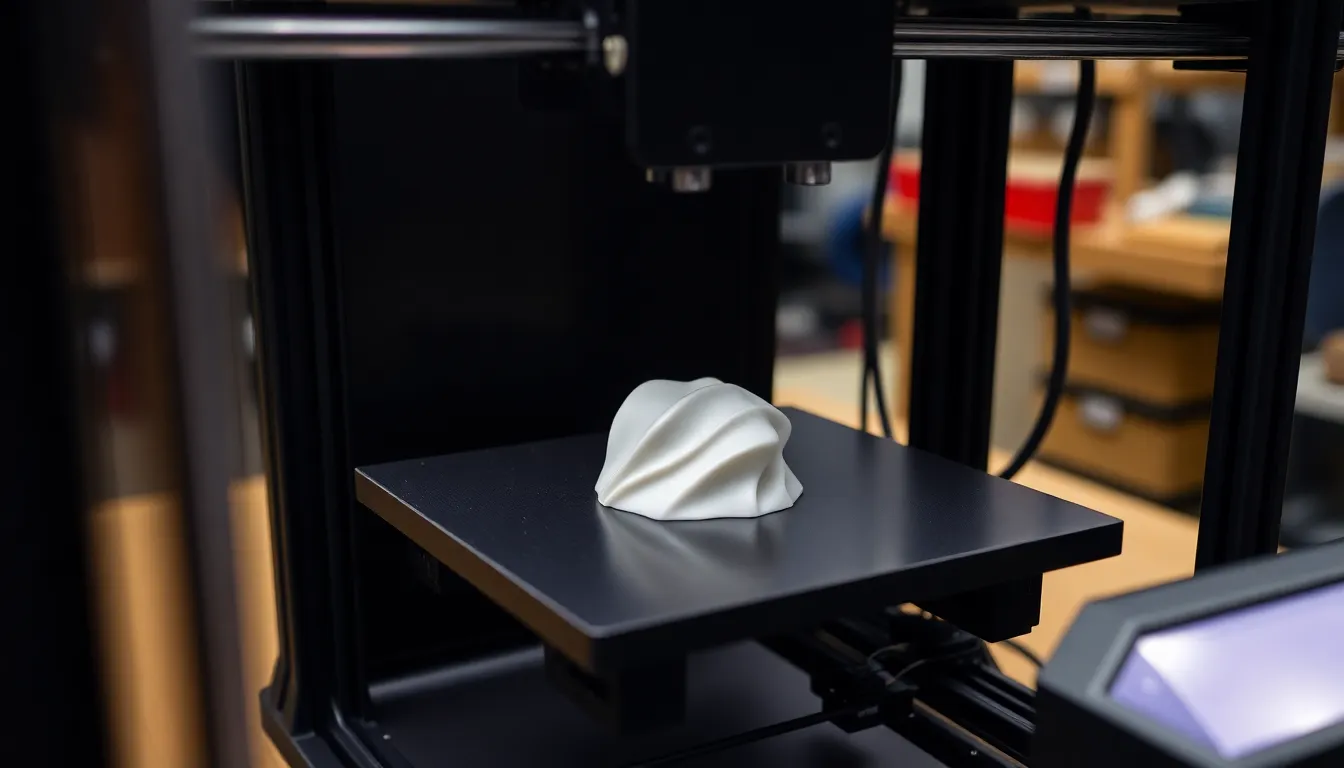

ToggleIn the wild world of 3D printing, where creativity meets technology, raft 3D printing stands out like a superhero in spandex. Imagine crafting intricate designs that float on a supportive platform, ensuring that your masterpiece doesn’t take a nosedive into the abyss of failed prints. Rafts are the unsung heroes of the 3D printing realm, providing stability and adhesion when the stakes are high.

But let’s be real—who wouldn’t want their 3D creations to have a solid foundation? With raft printing, not only do you get a sturdy base, but you also unlock the potential for flawless prints that leave everyone wondering if you’ve got a magic wand hidden in your workshop. Dive into the world of raft 3D printing and discover how this simple technique can elevate your projects from mediocre to magnificent.

Overview of Raft 3D Printing

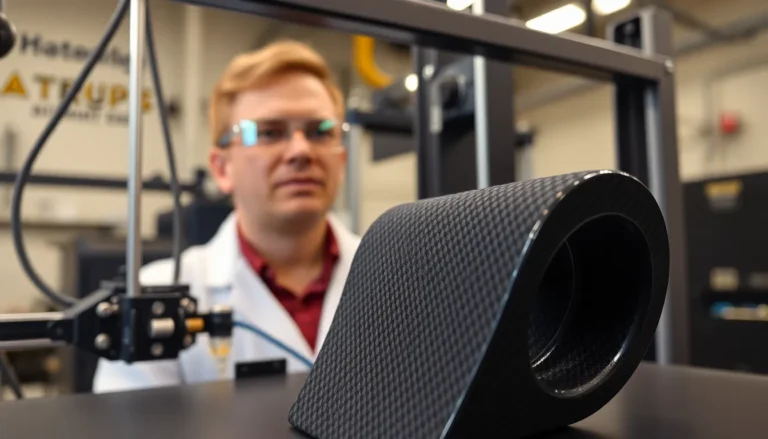

Raft 3D printing plays a vital role in ensuring the success of complex models. This technique involves creating a base layer beneath the actual print, which enhances stability throughout the printing process. By providing a solid foundation, rafts significantly reduce the chances of warping, especially in materials prone to shrinking during cooling.

Support structures like rafts are crucial for achieving accurate dimensions and details in printed objects. They improve adhesion between the 3D printer bed and the print itself, which minimizes the risk of detachment during the build. When dealing with challenging geometries, using a raft often becomes necessary to support overhangs and bridges.

Manufacturers frequently recommend raft printing for specific materials, such as PLA and ABS. Certain filaments may require additional adhesion techniques, making rafts an attractive option. Heavier prints benefit immensely from this method, as it ensures they remain anchored to the build plate.

Raft thickness can vary depending on the project requirements. A thicker raft provides more stability but may consume additional filament. Designers often adjust raft parameters in their slicing software to optimize the printing process.

Many 3D printing enthusiasts find that rafts enhance the overall quality of their projects. Not only do they prevent failed prints, but they also help achieve smoother finishes on the bottom surfaces of the final product. Embracing this technique often results in transformative improvements for intricate designs.

Benefits of Raft 3D Printing

Raft 3D printing offers several advantages that significantly enhance the quality and success of printed models. Key benefits include improved adhesion and enhanced surface finish.

Improved Adhesion

Using rafts provides a broader base for models, which enhances their grip on the build plate. Increased surface area ensures less chance of warping and detachment during the printing process. Rafts work especially well with materials such as PLA and ABS, creating a secure foundation. This feature proves crucial when printing complex geometries that require precision. As a result, many users experience a reduction in failed prints. Adjusting raft thickness allows for customization, catering to specific project needs. Ultimately, adopting rafts can mitigate common adhesion challenges faced by 3D printing enthusiasts.

Enhanced Surface Finish

Rafts contribute to a smoother appearance on the final product. They absorb potential imperfections from the build plate, leading to better overall surface quality. The initial layer of the raft can correct minor discrepancies on the plate, ensuring that the actual print adheres properly. Many find that the use of rafts helps achieve finer details in intricate designs while improving aesthetic appeal. Adjusting raft parameters helps to create a tailored solution for each print. This benefit proves especially valuable for projects requiring high-quality finishes. Overall, using rafts enhances both the functionality and look of 3D printed models.

Challenges of Raft 3D Printing

Despite its benefits, raft 3D printing presents several challenges that can affect users’ experiences.

Material Waste

Material waste becomes a significant concern when using rafts. Extra filament is required to create the raft layer, which can lead to increased costs, especially for large prints. Notably, the thickness of the raft can contribute to waste; thicker rafts consume more material. This excess consumption can deter environmentally conscious users who prefer sustainable practices. Additionally, the type of filament also affects waste levels; certain materials exhibit higher waste percentages compared to others. Users often seek ways to minimize this waste by adjusting raft parameters, yet waste remains an inherent drawback.

Increased Print Time

Increased print time often results from the use of rafts. The additional layer requires extra time for the printer to complete before starting the main model. Consequently, complex models with thicker rafts may take significantly longer to produce. Users frequently experience delays, particularly when balancing speed and quality in their projects. Furthermore, reliance on rafts can lead to longer maintenance time while waiting for prints to finish. Efficient time management becomes crucial for those who prioritize production timelines, particularly in busy work environments.

Best Practices for Raft 3D Printing

Raft 3D printing requires specific settings and materials for optimal results. Appropriate adjustments lead to enhanced adhesion and quality prints.

Ideal Settings and Materials

Utilizing the right materials can make a significant difference in raft performance. PLA and ABS work exceptionally well due to their adhesive properties. Adjusting the nozzle temperature can improve filament flow; for PLA, aim for around 200°C, while for ABS, approximately 240°C proves effective. Bed temperatures play a crucial role too; set the heated bed to around 60°C for PLA and 100°C for ABS. Layer height also impacts the output; smaller layer heights in the range of 0.1mm to 0.2mm enhance print detail. Lastly, consider a suitable build surface, such as glass or PEI, to further improve adhesion.

Troubleshooting Common Issues

Addressing common issues can streamline the raft printing process significantly. Warping often occurs due to insufficient bed temperature; increase the bed heat for enhanced adhesion. Users may encounter poor adhesion of the raft itself; adjusting the raft thickness can provide added stability. Clogged nozzles impede material flow; regular cleaning techniques should prevent this issue. Users should also monitor print speeds, as excessively fast settings can lead to layer misalignment. Rafts may require removal in certain situations; using a suitable tool, such as a spatula, can help detach them easily without damaging the model. These strategies ensure smoother printing experiences and higher-quality outcomes.

Raft 3D printing stands out as an essential technique that enhances the stability and quality of printed models. By providing a solid foundation, it significantly reduces the risk of warping and detachment, particularly for complex geometries. While there are considerations regarding material waste and print time, the advantages often outweigh these challenges.

Users can achieve smoother finishes and improved adhesion by customizing raft parameters to fit specific project needs. As 3D printing continues to evolve, embracing raft printing can lead to transformative results, making it a valuable tool for both beginners and experienced enthusiasts. Exploring this technique can unlock new possibilities in 3D design and production.