Table of Contents

ToggleImagine a world where your wildest design dreams come to life faster than you can say “carbon fiber.” Enter carbon fiber 3D printing, the superhero of the manufacturing world, swooping in to save the day with its incredible strength and versatility. This technology isn’t just for engineers and tech geeks; it’s for anyone who wants to turn their ideas into reality—without the hassle of traditional methods.

What Is Carbon Fiber 3D Printing?

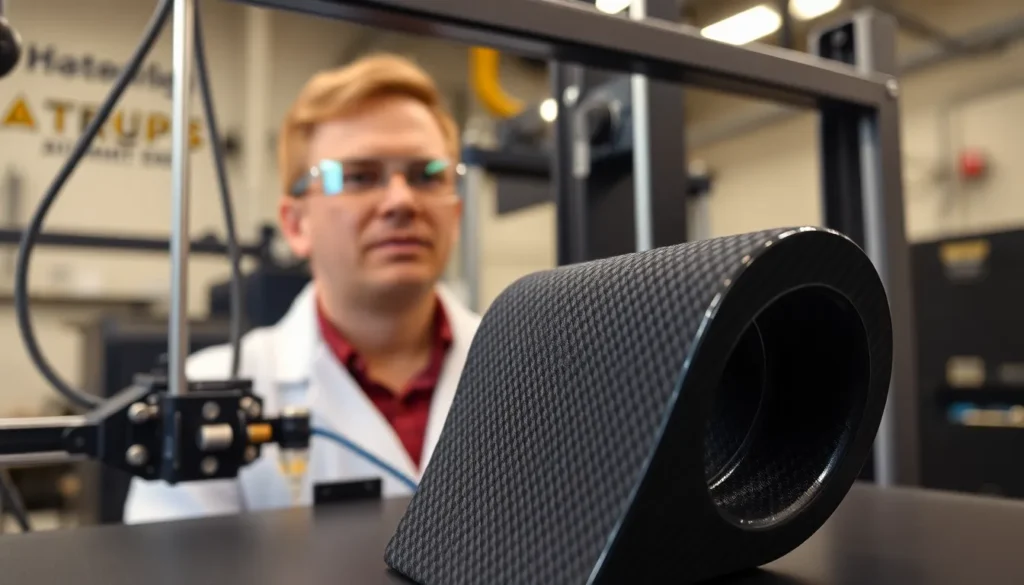

Carbon fiber 3D printing uses advanced techniques to fuse carbon fiber strands with thermoplastics. This combination creates components that boast high strength and lightweight properties. Known for its versatility, carbon fiber enhances various industries, from aerospace to automotive.

In this process, printers employ materials like nylon reinforced with carbon fiber filaments. The result is parts that resist bending or breaking under stress. Users appreciate the quicker production times compared to traditional manufacturing methods.

Applications span several fields. Aerospace companies utilize carbon fiber 3D printing for lightweight structural components. Automotive manufacturers also leverage this technology to produce durable vehicle parts. Other sectors finding success include medical, sporting goods, and consumer electronics.

Cost efficiency emerges as another advantage. While initial investments in carbon fiber printers may seem high, the reduced material waste and faster production times translate to long-term savings. Engineers often prefer this method for prototyping due to its rapid turnaround.

Quality remains paramount. The solid layered construction of carbon fiber 3D printed objects ensures precise detailing and superior strength. Manufacturers can achieve intricate designs that maintain structural integrity.

Accessibility factors also play a role. Hobbyists and small businesses now find advanced equipment more affordable than in the past. This democratization of technology promotes innovation across different user levels.

As carbon fiber 3D printing continues to evolve, its potential expands. Companies innovate to incorporate newer materials and enhance printing speed. Future developments could lead to even more diverse applications and improved efficiency.

Applications of Carbon Fiber 3D Printing

Carbon fiber 3D printing finds applications across multiple industries, showcasing its versatility and efficiency.

Aerospace Industry

In the aerospace sector, carbon fiber 3D printing plays a critical role in producing lightweight structural components. Aircraft manufacturers leverage this technology to reduce overall weight, which enhances fuel efficiency. Designers create complex geometries that traditional methods can’t achieve, boosting performance while minimizing cost. Parts like brackets, ducts, and housings benefit from the strength and durability offered by carbon fiber composites. The ability to customize parts on demand allows for rapid prototyping and testing, leading to faster development cycles.

Automotive Industry

The automotive industry increasingly utilizes carbon fiber 3D printing for producing high-performance parts. Lightweight components lead to improved fuel efficiency and handling, essential for performance cars. Manufacturers produce everything from interior parts to exterior panels using this technology. Customization options enable rapid iteration of designs, allowing engineers to test and validate prototypes quickly. This method also enhances the production of complex geometries that cater to unique vehicle designs. As a result, automakers achieve significant weight reductions without compromising structural integrity.

Medical Devices

Carbon fiber 3D printing significantly impacts the medical device industry by enabling the creation of custom prosthetics and implants. Customization ensures that devices meet individual patient needs, improving comfort and functionality. Techniques allow for precision manufacturing of complex shapes that fit specific anatomical requirements. Furthermore, the lightweight nature of carbon fiber enhances the usability of medical devices. High strength ensures durability, crucial in applications where failure is not an option. Rapid prototyping accelerates the testing phase, allowing for quicker advancements in medical technologies.

Advantages of Carbon Fiber 3D Printing

Carbon fiber 3D printing offers several compelling benefits that make it a valuable manufacturing option across various industries.

Strength and Durability

Strength stands out as a primary advantage of carbon fiber 3D printing. Components produced through this method exhibit remarkable tensile strength, often exceeding that of traditional materials like aluminum and steel. Durability remains another critical aspect, with carbon fiber parts resisting impact and wear even in demanding environments. Structures fabricated using reinforced nylon can withstand significant stress without deformation. In contrast to conventional manufacturing techniques, carbon fiber 3D printing allows for complex designs without compromising structural integrity. This technology supports industries like aerospace and automotive, where strong, reliable components are essential for performance and safety.

Lightweight Components

Lightweight components represent a key benefit of carbon fiber 3D printing. Carbon fiber’s low density enables the creation of parts that significantly reduce overall weight without sacrificing strength. Engineers optimize designs to achieve better fuel efficiency and enhanced performance, particularly in aerospace applications. The reduced weight of automotive parts contributes to improved handling characteristics and responsiveness. Manufacturers can produce intricate geometries that are not feasible with heavier traditional materials. Overall, the lightweight nature of carbon fiber components facilitates innovative designs while promoting efficiency in production and operation.

Challenges of Carbon Fiber 3D Printing

Carbon fiber 3D printing presents several challenges that users must navigate. Understanding these challenges helps in optimizing the use of this innovative technology.

Cost Considerations

Costs can escalate quickly with carbon fiber 3D printing due to the high price of materials. Filaments reinforced with carbon fiber typically cost more than standard thermoplastics, impacting budget allocations. Production equipment also requires a significant investment, including specialized printers designed to handle composite materials. Maintenance costs can prove higher as well, due to the complexity of the machinery. While long-term savings arise from reduced material waste and faster production times, initial expenses may deter some users from adopting this technology.

Printing Techniques

Various printing techniques used in carbon fiber 3D printing introduce unique challenges. Fused deposition modeling (FDM) often remains popular due to its accessibility, but it may struggle with consistent extrusion of carbon fiber filaments. Selective laser sintering (SLS) provides better layer adhesion, yet it requires significant upfront investment. Precision and accuracy can vary based on the technique employed. Post-processing steps may further complicate production, as finishing techniques depend on the desired surface quality. Understanding the strengths and weaknesses of each method significantly aids in selecting the right approach for specific applications.

Future Trends in Carbon Fiber 3D Printing

Ongoing developments in carbon fiber 3D printing drive innovation across numerous sectors. Advancements in material science lead to stronger and lighter composites, enhancing part performance. Research indicates the emergence of bio-based carbon fibers, which promote sustainability and reduce environmental impact.

Increased automation in the printing process accelerates production times. Smart technology integration allows for real-time monitoring, reducing defects and ensuring high-quality output. Companies adopting industry 4.0 practices benefit from interconnected systems that improve workflow efficiency.

Customization becomes more accessible due to expanding software capabilities. Users can design intricate geometries tailored to specific project requirements effortlessly. Enhanced user-friendly design tools make it easier for non-experts to create custom solutions.

Furthermore, hybrid printing techniques gain traction. Combining additive and subtractive manufacturing enables the production of complex shapes while enhancing surface finishes. By integrating multiple processes, manufacturers can achieve higher precision and efficiency during production.

Supply chain optimization presents another key trend. Localized production minimizes transportation costs and reduces lead times. Companies explore on-demand production strategies, decreasing inventory holding and allowing for rapid adjustments based on market demand.

Market demand for lightweight components grows, particularly in aerospace and automotive industries. According to industry reports, carbon fiber 3D printing contributes significantly to fuel-efficient designs, supporting manufacturers in meeting regulatory and performance requirements.

Continuous exploration of post-processing methods enhances end product qualities. Techniques such as surface treatments and coatings improve wear resistance and aesthetics. Overall, trends indicate a dynamic future for carbon fiber 3D printing, characterized by innovative applications and increased market adoption.

Carbon fiber 3D printing is transforming the landscape of manufacturing. Its unique combination of strength and lightweight properties makes it an ideal choice for various industries. As accessibility improves and costs decrease, more users are embracing this technology for innovative applications.

The ongoing advancements in materials and techniques promise to enhance the capabilities of carbon fiber 3D printing. With a focus on sustainability and customization, the future looks bright for this dynamic field. As industries continue to explore its potential, carbon fiber 3D printing will play a crucial role in shaping the next generation of products and solutions.