Table of Contents

ToggleIn a world where creativity knows no bounds, 3D printing silicone is like the Swiss Army knife of manufacturing. Imagine crafting everything from custom prosthetics to playful kitchen gadgets with just a few clicks. It’s not magic; it’s technology, and it’s changing the game one layer at a time.

What Is 3D Printing Silicone?

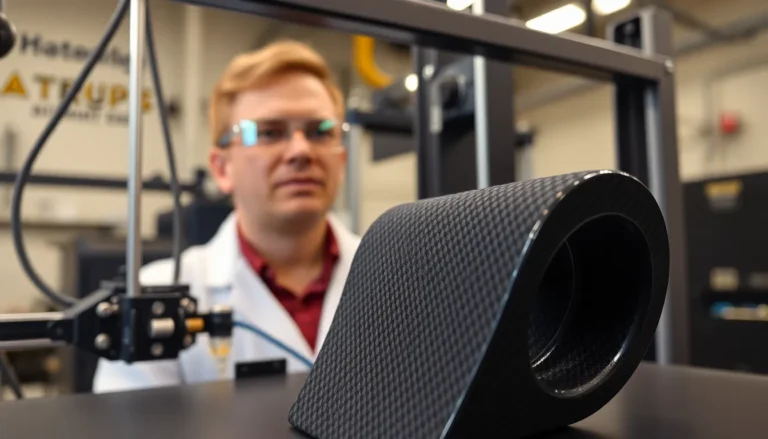

3D printing silicone refers to the process of using additive manufacturing techniques to create objects from silicone materials. This technology allows for precise control over the shape and texture of the final product. It enables manufacturers to produce complex geometries that were previously challenging or impossible to achieve with traditional silicone molding methods.

Various applications utilize 3D printing silicone. Custom prosthetics often benefit from tailored designs that fit the user perfectly, enhancing comfort and functionality. In the culinary field, it creates unique kitchen gadgets that cater to specific cooking needs. Flexible and durable properties of silicone offer significant advantages in these areas.

Silicone’s versatility plays a crucial role in this process. Different types of silicone, such as thermosetting and thermoplastic, each have unique characteristics suitable for specific applications. The choice of material affects the flexibility, heat resistance, and overall performance of the printed object.

Recent advancements in 3D printing technology facilitate the use of silicone in different domains. Innovations such as digital light processing (DLP) and continuous liquid interface production (CLIP) allow for faster print times and improved resolution. These methods contribute to the growing popularity of 3D printing silicone for both prototyping and production.

Sustainability considerations also influence the adoption of 3D printing silicone. Many manufacturers explore eco-friendly silicone materials to reduce environmental impact. By leveraging 3D printing techniques, they can minimize waste associated with traditional manufacturing practices, fostering a more sustainable approach to production.

This combination of flexibility, precision, and sustainability positions 3D printing silicone as a transformative manufacturing tool in various industries.

Benefits of 3D Printing Silicone

3D printing silicone offers numerous advantages that enhance its appeal across various industries.

Versatility in Applications

3D printing silicone provides solutions for a wide range of applications. Custom prosthetics benefit from precise fit and enhanced comfort, which traditional methods might not achieve. Innovative kitchen gadgets can be produced with unique designs tailored to specific culinary tasks. Automotive parts also see improvements in durability and flexibility, catering to diverse industry needs. This technology allows for intricate geometries and customized shapes, making it an essential tool in modern manufacturing.

Cost-Effectiveness

Cost savings emerge as a significant benefit of 3D printing silicone. Reduced material waste compared to traditional techniques lowers overall production costs. Shortened production times allow manufacturers to bring products to market faster, enhancing profitability. Smaller batch sizes are feasible without incurring excessive expenses, catering to businesses with varied demands. This efficiency not only optimizes manufacturing processes but also contributes positively to a business’s bottom line.

Customization Capabilities

Customization stands out as a key advantage in 3D printing silicone. Manufacturers can create personalized products that meet specific user requirements. From individual comfort preferences for prosthetics to tailored designs for unique kitchen tools, options are vast. Modifying existing designs is straightforward, enabling quick adjustments based on feedback. Such flexibility in design enhances user satisfaction, making 3D printed silicone a preferred choice in many sectors.

The 3D Printing Process for Silicone

3D printing silicone involves specific materials and techniques that enhance the process’s effectiveness. Understanding these components helps clarify how 3D silicone printing operates.

Materials Used in 3D Printing Silicone

Silicone materials in 3D printing vary based on application requirements and desired properties. Liquid silicone rubber (LSR) stands out for its flexibility and durability, making it ideal for products needing elasticity. Additionally, heat-resistant silicone is useful for kitchen gadgets and various industrial parts. Other materials, like silicone blends, combine characteristics to create customizable solutions for specific tasks. Each variant allows for unique functionalities tailored to user demands.

Techniques for 3D Printing Silicone

Various techniques exist for 3D printing silicone, and advancements continue to shape the field. Digital light processing (DLP) offers excellent resolution and speed, allowing detailed silicone designs. Continuous liquid interface production (CLIP) enhances print times while reducing material waste. Other methods, such as extrusion-based techniques, apply pressure to deposit silicone layers precisely. Each technique delivers different advantages, making silicone 3D printing versatile for diverse applications across multiple industries.

Challenges in 3D Printing Silicone

3D printing silicone presents unique challenges that can affect the quality and efficiency of production. Understanding these obstacles is crucial for optimizing the process.

Material Limitations

Material properties can restrict the use of certain silicone types in 3D printing. For instance, some silicone formulations lack the necessary viscosity, making it difficult to achieve accurate prints. Surface adhesion issues often arise, leading to layer separation during the printing process. In addition, the durability of certain silicone types can limit their application in high-stress environments. Not all silicone materials are compatible with specific printing technologies, which impacts design flexibility. Different silicates may also exhibit poor curing characteristics, resulting in subpar end products.

Technical Challenges

Technical hurdles often impede the smooth operation of 3D printing silicone. Print speed is a significant concern, as longer printing times can affect overall productivity. Precision control presents another challenge; achieving fine details requires advanced equipment and settings. Calibration of printers is essential, but any deviation can lead to defects in the finished product. Furthermore, post-processing needs for silicone parts may complicate the workflow. Many prints require extensive curing processes, which add time and cost to the project.

The emergence of 3D printing silicone is reshaping manufacturing landscapes across multiple sectors. Its ability to produce customized and complex designs offers unparalleled advantages in comfort and functionality. As technology continues to advance the process, manufacturers can expect improved efficiency and sustainability.

Despite the challenges that come with 3D printing silicone, the benefits far outweigh the drawbacks. The potential for innovation in areas like healthcare and consumer products is immense. With ongoing developments in materials and techniques, 3D printing silicone is set to become a cornerstone of modern manufacturing. Embracing this technology will not only enhance product offerings but also drive industry standards toward a more sustainable future.