Table of Contents

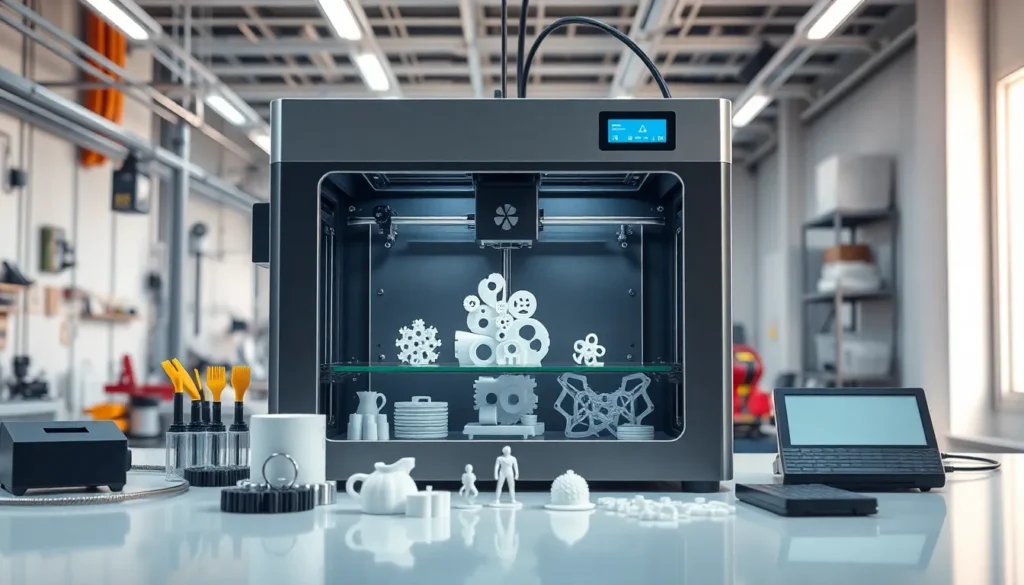

ToggleThe 3D printing market is booming faster than a kid in a candy store. With its ability to turn digital designs into tangible objects, it’s not just a trend—it’s a revolution. From healthcare to aerospace, industries are discovering how this technology can save time, reduce waste, and spark creativity.

But what’s really happening behind the scenes? As businesses scramble to embrace this innovative tech, understanding the market dynamics becomes crucial. This analysis dives deep into the current state of 3D printing, exploring growth trends, challenges, and opportunities that could have even the most seasoned investors doing a happy dance. Buckle up as we unravel the fascinating world of 3D printing and why it’s more than just a quirky hobby for tech enthusiasts.

Overview of 3D Printing Market

3D printing exhibits remarkable growth trends across multiple sectors. Current market analysis shows a compound annual growth rate (CAGR) of approximately 25.76% from 2022 to 2030. Key industries embracing this technology include healthcare, aerospace, automotive, and consumer goods. Each sector benefits from reduced lead times and increased design flexibility.

Healthcare applications focus on creating custom prosthetics and implants. This sector highlights the technology’s ability to produce tailored solutions that enhance patient care. Aerospace companies utilize 3D printing for manufacturing lightweight components, leading to fuel efficiency and cost savings. Automotive industries find value in rapid prototyping and tooling, thus accelerating product development cycles.

Challenges in the 3D printing market often revolve around material limitations and regulatory hurdles. Material selection impacts the functionality of printed products, making it critical to innovate new options. Additionally, navigating complex regulations, particularly in healthcare applications, presents ongoing challenges for manufacturers.

Emerging opportunities are abundant in the 3D printing landscape. Companies increasingly look toward integrating artificial intelligence to optimize design and production processes. Sustainability initiatives drive interest in biodegradable materials and energy-efficient printing methods. As these trends evolve, investors recognize the potential for returns in this dynamic market.

Overall, the 3D printing landscape is poised for continued expansion. Insights indicate a shift towards larger-scale manufacturing and on-demand production models. These developments signify a transformative period for industries leveraging 3D printing technology.

Key Trends in 3D Printing

3D printing is experiencing transformative trends that shape its future across various sectors. Notably, technological advancements and industry applications play crucial roles in this rapidly evolving market.

Technological Advancements

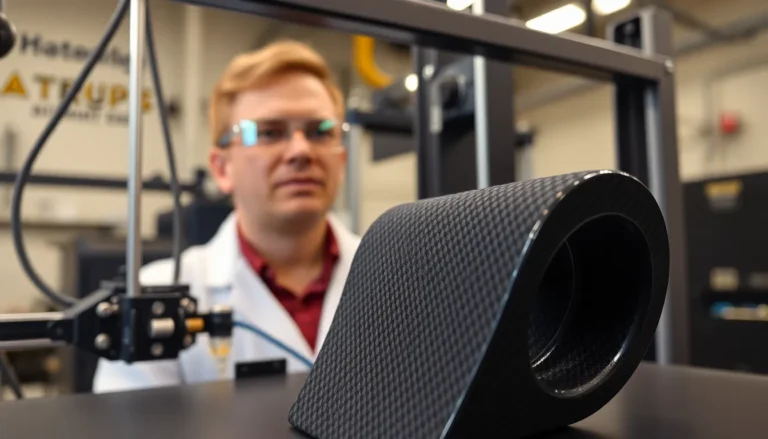

Innovations in 3D printing technology lead to improved capabilities and expanded material options. Enhanced precision and speed in printing processes enhance production efficiency. Companies increasingly adopt multi-material printing techniques, allowing for complex designs and greater functionality in printed objects. Furthermore, the integration of artificial intelligence streamlines design workflows and optimizes production schedules. In addition, developments in software for 3D modeling empower users to create sophisticated designs easily. These advancements drive the market’s compound annual growth rate of approximately 25.76% from 2022 to 2030.

Industry Applications

Various industries leverage 3D printing for unique applications, transforming traditional manufacturing methods. In healthcare, professionals utilize 3D printing for creating custom prosthetics and organ models, significantly improving patient outcomes. Aerospace industries benefit from printing lightweight components, achieving fuel efficiency and reducing costs. Additionally, the automotive sector embraces this technology for rapid prototyping, decreasing development timelines while increasing innovative designs. Consumer goods companies also explore 3D printing, aiding in the creation of personalized products. Overall, these applications exemplify the versatility and transformative potential of 3D printing across multiple fields.

Regional Market Analysis

The 3D printing market exhibits distinct dynamics across various regions, influenced by technological advancements, industry demands, and regulatory environments.

North America

North America leads the 3D printing market, leveraging strong investments in research and development. The United States accounts for a significant portion of the market share, driven by advancements in healthcare applications, aerospace innovations, and consumer products. Companies like 3D Systems and Stratasys play essential roles in technology propagation. In 2022, the market was valued at approximately $1.1 billion and is projected to expand steadily, fueled by the demand for rapid prototyping and customized solutions.

Europe

Europe ranks as a key competitor in the 3D printing landscape, particularly through advancements in additive manufacturing. Germany and the United Kingdom are at the forefront, attracting investment in industrial and healthcare applications. Regulatory frameworks support innovation while emphasizing safety and quality standards. The European market reached a valuation of around $900 million recently, with projections indicating sustained growth due to increased adoption in automotive and defense sectors.

Asia-Pacific

Asia-Pacific experiences rapid growth in 3D printing technologies, with countries like China, Japan, and India leading the way. China, in particular, focuses on enhancing large-scale manufacturing capabilities, significantly impacting the market landscape. This region’s market was valued at approximately $800 million in 2022, with rapid advancements in materials and techniques driving adoption across various industries. Key players include such as Hirotech and Shining 3D, bolstering domestic production and innovation while catering to emerging market needs.

Competitive Landscape

The 3D printing market features a dynamic competitive environment driven by key players and market share influences.

Major Players

Leading companies in the 3D printing market include Stratasys, 3D Systems, and Ultimaker. Stratasys provides a wide range of printers and materials, targeting diverse industries, particularly in aerospace and automotive. 3D Systems excels in offering both hardware and software solutions, focusing on additive manufacturing processes that improve efficiency. Ultimaker specializes in desktop 3D printers, catering to educational and small business sectors. Additionally, HP and GE Additive are increasingly influential, pushing innovations in large-scale production and industrial applications.

Market Share Analysis

North America commands a significant share of the global 3D printing market. Analysts estimate that this region accounted for approximately 38% of the market in 2022, driven by strong investments in research and development. Europe follows, with around 30% market share, led by countries like Germany and the UK, which emphasize safety in manufacturing. The Asia-Pacific region is rapidly expanding, contributing about 22% of the market. China takes the lead here, advancing in large-scale production capabilities and technological innovations. Overall, shifting dynamics indicate that opportunities for growth and collaboration among these players will continue to reshape the competitive landscape.

Future Projections

The 3D printing market is set for significant advancements through 2030. A projected compound annual growth rate (CAGR) of approximately 25.76% underscores this growth trajectory. Innovations like artificial intelligence integration will streamline design and production processes, enhancing efficiency and product quality.

Potential applications in healthcare are expanding. Custom prosthetics and organ models already demonstrate the impact of 3D printing on patient care. As technologies improve, expect more hospitals to adopt these solutions, producing personalized medical devices on-site.

Aerospace companies increasingly rely on 3D printing. Lightweight components manufactured through additive techniques yield better fuel efficiency. Enhanced production speeds also reduce turnaround time, allowing for rapid responses to market demands.

The automotive sector values rapid prototyping. With accelerated product development cycles, manufacturers can introduce innovative designs while minimizing costs. Improved printing technologies will further drive this efficiency.

Consumer goods firms explore personalization through 3D printing. Unique product creation engages customers and fosters brand loyalty. This trend will likely expand, prompting brands to invest in tailored production methods.

Regional dynamics will also shape market growth. North America leads, with strong investments in research and development. Countries such as Germany in Europe and China in Asia-Pacific support booming additive manufacturing industries, driving competition.

Competitive landscapes adapt to these trends. Key players like Stratasys, 3D Systems, and Ultimaker target specific sectors, each contributing unique innovations. This adaptability ensures the continued evolution of the 3D printing market, paving the way for larger-scale manufacturing and on-demand production models.

The 3D printing market is on a trajectory of remarkable growth and innovation. With its ability to revolutionize industries from healthcare to aerospace the technology offers unprecedented opportunities for efficiency and creativity. As companies continue to embrace advancements in materials and processes the potential for personalized and sustainable production becomes increasingly viable.

Emerging trends such as artificial intelligence integration and multi-material printing are set to further enhance capabilities. Regional dynamics will play a crucial role in shaping the competitive landscape as North America Europe and Asia-Pacific drive forward with unique strategies and innovations. The future of 3D printing holds promise not just as a manufacturing tool but as a catalyst for transformative change across various sectors.