Table of Contents

ToggleIn a world where creativity knows no bounds, 3D printing supplies are the magical ingredients that turn dreams into reality. Imagine crafting everything from intricate jewelry to life-sized dinosaurs, all from the comfort of your home. With the right supplies, the only limit is your imagination—or perhaps your printer’s filament capacity.

Overview of 3D Printing Supplies

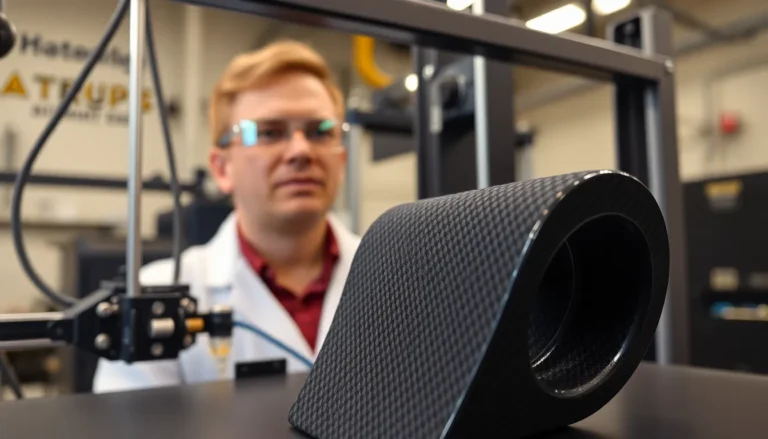

3D printing supplies include various materials and tools essential for creating objects. Understanding these supplies enhances the printing experience and maximizes potential outcomes.

Types of 3D Printing Supplies

Filaments are among the most common supplies. Options include PLA, ABS, and PETG, each offering distinct properties. Resins represent another category, primarily used in resin printers for high-detail projects. Additionally, powders serve specific printing methods like SLS, effectively creating prototypes and parts.

Accessories also play a significant role in successful 3D printing. Tools such as extruders, hotends, and build plates contribute to the quality of printed items. Maintenance supplies, including lubricants and cleaning kits, ensure printers operate smoothly and efficiently.

Key Features to Consider

Print quality significantly depends on filament type and compatibility with printers. Diameter impacts the extrusion process, with common sizes being 1.75 mm and 2.85 mm. Temperature tolerance defines how materials behave during printing. Knowledge of melting and cooling points influences printing settings.

Color options allow for creative designs, enhancing aesthetic appeal. Availability of specialty filaments, like flexible or glow-in-the-dark variations, adds uniqueness to projects. Compatibility with specific printers remains crucial, as not all materials work with every machine. Selecting appropriate supplies ensures optimal printing results, leading to successful creation.

Popular Materials for 3D Printing

Various materials enhance the 3D printing experience, each serving unique needs and applications. Below are some of the most popular choices.

Filaments

Filaments serve as the primary material for fused deposition modeling (FDM) printers. PLA, a common option, offers ease of use and biodegradability, making it ideal for beginners. ABS, known for its strength and heat resistance, suits applications that require durability. PETG blends the benefits of both PLA and ABS, providing flexibility and reliability for functional parts. Each filament type has specific temperature settings, generally ranging from 190 to 260 degrees Celsius. Users select filaments based on desired print quality and intended use.

Resins

Resins cater to stereolithography (SLA) and digital light processing (DLP) printers, enabling high-detail, smooth finishes. Standard resin allows for fine details, making it perfect for intricate models and figurines. Flexible resin offers elasticity, providing a soft-touch finish for wearable items. Tough resin combines strength with impact resistance, ideal for functional prototypes. Factors such as curing time and post-processing requirements vary across resin types, influencing user choices. Ensuring compatibility with specific printers maximizes the printing experience.

Essential Tools and Accessories

3D printing requires various tools and accessories for optimal performance and creativity. Understanding each component helps users maximize their printing experience.

Printers

Fused deposition modeling printers, commonly known as FDM printers, remain popular for desktop 3D printing. Many users prefer PLA for its ease of use, while others opt for ABS due to its durability. Temperature settings play a crucial role in print quality and material compatibility. Choosing a printer that meets specific project needs ensures efficient production. Brands like Prusa and Creality have established a solid reputation for reliability and performance.

Extruders and Hotends

Extruders and hotends significantly impact the printing process and material flow. Heaters within hotends melt filament, while extruders push the filament through the hotend. Users can select all-metal hotends for higher-temperature materials or standard ones for versatile options. Upgrading to a dual extruder allows printing with multiple filaments, enhancing design capabilities. Regular maintenance of these components helps prevent clogs and ensures smooth operation.

Purchasing Considerations

When selecting 3D printing supplies, several key factors influence the overall experience and success of projects.

Cost vs. Quality

Cost often plays a crucial role in purchasing decisions for 3D printing supplies. Higher-quality materials tend to exhibit better durability and print fidelity. While budget-friendly options are available, they might compromise on print quality or consistency. Users often find that investing in reputable brands, like Prusa or Creality, leads to more reliable results over time. Filament pricing typically varies based on material type; for instance, PLA usually costs around $20 per kilogram, while specialty filaments might exceed $40. Longer-lasting supplies ultimately reduce the need for frequent replacements, which can add to overall savings.

Supplier Reputation

Supplier reputation significantly affects the reliability of 3D printing supplies. Trusted suppliers often provide comprehensive product information, customer support, and warranty options. Users should research reviews and testimonials to gauge experiences with specific brands or retailers. A reputable supplier is more likely to ensure product quality and consistency, reducing issues during printing sessions. Many experienced users recommend purchasing from established companies with a track record of reliability. This consideration helps avoid complications such as inconsistent filament diameter or subpar resin performance, leading to smoother printing experiences overall.

Exploring the world of 3D printing supplies opens up a realm of creative opportunities. With the right materials and tools in hand, anyone can bring their imaginative designs to life. Selecting suitable filaments and resins is crucial for achieving the desired results while ensuring compatibility with specific printers enhances the overall experience.

Investing in high-quality supplies pays off in the long run by improving durability and print fidelity. Users should prioritize reputable suppliers to avoid complications that can hinder projects. By understanding the essentials of 3D printing supplies, individuals can confidently embark on their creative journeys and unlock the full potential of their printers.