Table of Contents

ToggleIn a world where ideas can take shape faster than a magician pulling a rabbit from a hat, 3D printing prototypes are the ultimate game-changer. Gone are the days of waiting weeks for a design to come to life. Now, with a sprinkle of creativity and a dash of technology, anyone can transform a digital concept into a tangible reality in mere hours.

Imagine impressing your colleagues with a prototype that went from “just an idea” to “look what I’ve made!” faster than you can say “layer by layer.” Whether you’re an entrepreneur with a brilliant invention or a hobbyist with a quirky vision, 3D printing opens the door to endless possibilities. Dive into the world of 3D printing and discover how it can revolutionize your prototyping process while keeping your budget intact and your stress levels low.

What Are 3D Printing Prototypes?

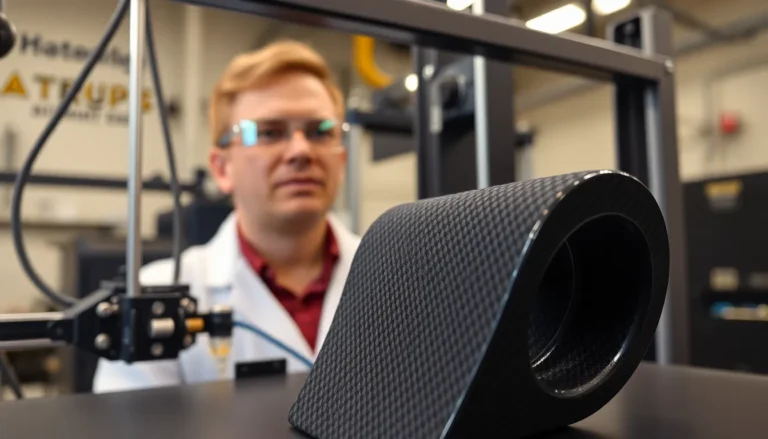

3D printing prototypes represent a physical manifestation of digital designs. These prototypes serve various purposes, including testing, validating ideas, and communicating concepts. Designers and engineers utilize this technology to create models that enhance understanding of functionality and aesthetics.

Rapid production is a defining feature of 3D printing prototypes. Within hours, users can transform intricate designs into tangible objects. This speed allows for swift iterations, leading to faster project development cycles.

Cost-effectiveness plays a crucial role in the appeal of 3D printing prototypes. Traditional manufacturing methods often require significant investments in materials and production processes. In contrast, 3D printing minimizes waste through additive manufacturing, ensuring efficient use of resources.

Versatility contributes to the usefulness of 3D printing prototypes. Users can experiment with a wide range of materials, including plastics, ceramics, and metals. Each material allows for unique properties and applications suited for different industries.

Feedback from stakeholders can significantly improve product development. Prototypes facilitate communication among team members, investors, and clients. Engaging with tangible prototypes helps gather insights, leading to informed decisions and refinements.

Industry adoption of 3D printing prototypes is on the rise. Professionals in sectors like aerospace, healthcare, and automotive are leveraging this technology for design optimization. Exploring the capabilities of 3D printing enables innovators to push boundaries in product design and functionality.

Benefits of 3D Printing Prototypes

3D printing prototypes offer numerous advantages that enhance the prototyping process and product development. Two critical benefits are cost-effectiveness and time efficiency.

Cost-Effectiveness

Cost-effectiveness stands out as a primary advantage of 3D printing prototypes. This technology significantly reduces material waste compared to traditional methods, allowing for more economical use of resources. Budget constraints often limit innovation; however, 3D printing lowers production costs and enables more experimentation. Entrepreneurs and hobbyists can create multiple iterations without the financial burden tied to conventional fabrication processes. Also, prototyping in-house eliminates outsourcing expenses, enhancing control over project budgets. Overall, these cost benefits encourage creativity while making high-quality prototypes accessible.

Time Efficiency

Time efficiency plays a crucial role in the prototyping phase. 3D printing transforms digital designs into physical objects within hours, promoting rapid iteration cycles. Each prototype can be produced quickly, enabling teams to gather feedback and make adjustments promptly. Delays in conventional prototyping methods can stall product developments, but the speed of 3D printing accelerates the entire process. Rapid prototyping facilitates timely decision-making, allowing for quick market entry with refined products. Companies can thus enhance their competitive edge and support dynamic product development in fast-paced industries.

Applications of 3D Printing Prototypes

3D printing prototypes find extensive applications across numerous fields. This technology enhances product development and impacts the medical field significantly.

Product Development

In product development, 3D printing allows rapid creation of prototypes from digital designs. Designers can explore multiple iterations, refining products according to user feedback. Accelerated development minimizes the time from concept to market. Companies often experience reduced costs associated with traditional prototyping methods. Directly testing prototypes aids in identifying functional issues early in the design process. 3D printing accommodates a wide range of materials, ensuring that products are both innovative and practical. This flexibility supports diverse industries, including consumer electronics and automotive.

Medical Field

The medical field highly benefits from 3D printing prototypes. Customized implants and prosthetics can be manufactured to fit individual patient needs. Surgical models created from patient-specific data enhance preparation for intricate procedures. This process leads to improved surgical outcomes and reduced operation time. Training new surgeons using 3D printed anatomy models increases skills and confidence. Additionally, bioprinting technology is emerging, utilizing living cells to develop tissue and organ structures. Rapid prototyping enables medical professionals to innovate and adapt solutions quickly, addressing evolving healthcare challenges.

Challenges of 3D Printing Prototypes

3D printing prototypes presents several challenges that can affect the prototyping process. Addressing these hurdles enhances the overall effectiveness of this technology in various applications.

Material Limitations

Material limitations pose obstacles in 3D printing. Specific materials may not achieve the required strength or durability for prototype applications. Some plastics, for instance, are suitable for initial prototypes but lack the robustness needed for final products. Likewise, metals provide superior performance, yet they often require advanced printing systems, which can be costly. Accessibility to a broad range of materials can also vary based on technology and budget constraints. Additionally, material compatibility with the 3D printing process affects the results, emphasizing the need for careful selection to meet project specifications.

Technical Challenges

Technical challenges often arise during the 3D printing process. Calibration of printers proves essential for achieving precise results, as improper calibration can lead to design errors. Moreover, users may encounter issues with print resolution, impacting detail and surface finish. Software compatibility also presents a challenge; ensuring that design files translate accurately to the printer format is critical. Support structures sometimes complicate the printing process, necessitating additional time for design adjustments and post-processing. Professionals experiencing these technical difficulties must possess adequate troubleshooting skills to maintain efficiency and produce accurate prototypes.

The rise of 3D printing prototypes is reshaping industries and empowering creators. Its ability to transform digital designs into tangible objects within hours accelerates innovation and enhances product development. With cost-effective solutions and a vast range of materials, it encourages experimentation and rapid iterations.

As professionals in aerospace, healthcare, and automotive fields embrace this technology, they’re not just improving efficiency but also redefining what’s possible. The challenges that come with 3D printing may seem daunting, yet they offer opportunities for growth and learning. By tackling these hurdles, users can unlock the full potential of 3D printing, driving their projects toward success and bringing their ideas to life.