Table of Contents

ToggleIn a world where imagination meets technology, 3D modeling for printing is the magic wand everyone’s been waiting for. Gone are the days of sketching on napkins and hoping for the best. With 3D modeling, creativity transforms into tangible reality faster than you can say “extruder.” Whether it’s a prototype for your next big invention or a quirky figurine to impress your friends, the possibilities are endless.

Overview of 3D Modeling for Printing

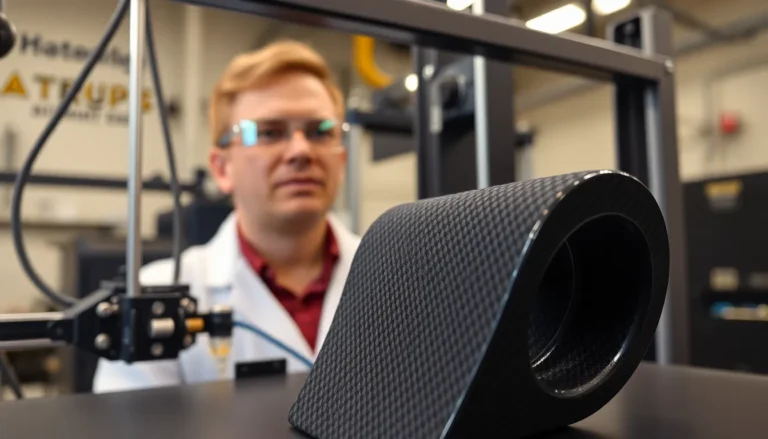

3D modeling for printing represents a significant advancement in design technology. This process converts digital designs into physical objects using additive manufacturing techniques. Artists, engineers, and hobbyists utilize software programs to create intricate models suited for various applications.

Applications in industries range from prototyping to manufacturing. Rapid prototyping plays a critical role in product development, allowing teams to visualize concepts early. Designers generate precise models to ensure fit and functionality before moving to production.

Design software encompasses several popular options. Autodesk Fusion 360 supports collaborative design, while Tinkercad offers beginner-friendly tools. Blender serves as a powerful platform for artists, catering to both novice and advanced users.

Considerations for successful 3D printing start with model design. Ensuring that models have the proper dimensions and tolerances is crucial for compatibility with 3D printers. Understanding the chosen printing method influences design decisions, such as materials used and layer resolution.

Material selection impacts the final product’s durability and appearance. Common materials include PLA for beginner projects and ABS for more robust applications. Each material has unique properties that dictate suitability for specific use cases.

Ultimately, 3D modeling for printing empowers creators by enhancing their ability to bring imaginative concepts to life. As technology advances, the range of possibilities continues to expand, fueling enthusiasm within diverse fields. Through careful planning and consideration, individuals can harness this innovative process to produce extraordinary items.

Benefits of 3D Modeling for Printing

3D modeling for printing offers numerous advantages, enhancing creativity and efficiency. Understanding these benefits can help creators leverage this technology effectively.

Cost Efficiency

Cost efficiency stands out as a primary advantage of 3D modeling for printing. This process minimizes material waste since designers can create precise models tailored to their specific requirements. Traditional manufacturing often results in excess material, leading to additional expenses. Rapid prototyping reduces production costs significantly by allowing for quick iterations and adjustments. Designers can test multiple versions without the expenses tied to conventional methods. Higher production rates emerge due to the swift turnaround times associated with additive manufacturing. Companies save not only money but also valuable resources, streamlining operations while improving overall profitability.

Design Flexibility

Design flexibility plays a crucial role in the appeal of 3D modeling for printing. Utilizing advanced software, creators can explore intricate designs that were previously impractical. The ability to modify shapes and dimensions easily encourages experimentation and creativity. Complex geometries and custom features become achievable, meeting diverse project requirements. Changes to the model occur rapidly, allowing designers to adapt based on feedback and test outcomes. Additionally, designers can produce multiple iterations concurrently, expediting the design process significantly. This flexibility fosters innovation, enabling artists and engineers to produce unique products that push the boundaries of design.

Common Software Used in 3D Modeling

Numerous software options exist for 3D modeling, catering to different needs and skill levels in printing. These programs empower users to create precise and intricate designs.

CAD Software Options

CAD software enables designers to create detailed models, bridging the gap between vision and production. Autodesk Fusion 360 combines parametric modeling with a user-friendly interface, making it suitable for beginners and experienced users alike. SolidWorks stands as another robust choice, popular among engineers for its advanced simulation tools. Rhino is known for its versatility, accommodating complex geometries, while Catia excels in aerospace and automotive applications. Each software offers unique features that enhance design capabilities, allowing for innovation in 3D printing.

Open-Source Alternatives

Open-source solutions provide accessible options for those on a budget. FreeCAD offers parametric modeling features, ideal for engineering and architecture projects. Tinkercad is beginner-friendly, enabling users to create simple designs through an intuitive browser-based interface. Blender, while primarily for animation, boasts powerful modeling tools for 3D printing needs. These alternatives encourage experimentation and creativity without significant financial investment, making 3D modeling more inclusive for all users.

Best Practices for 3D Modeling

Effective 3D modeling significantly enhances the printing process. Following best practices ensures successful outcomes in design and production.

Optimization Techniques

Optimizing models for 3D printing improves quality and efficiency. Use manifold geometry to prevent printing issues, ensuring all edges and vertices connect correctly. Incorporating appropriate wall thickness increases durability while maintaining design integrity. Minimize complex features and tiny details that don’t translate well during printing. Apply design rules specific to the printer type, adapting models for FDM, SLA, or SLS processes. Regularly check for non-manifold edges and inverted normals, as these can cause print failures. Finally, test prototypes to identify potential issues early, enhancing the overall print quality.

Preparing Models for Printing

Preparing models requires attention to detail and accuracy. First, set the correct scale, ensuring the model fits the desired specifications. Next, export designs in compatible file formats, such as STL or OBJ, suitable for most slicer software. Include support structures if necessary, as these assist in printing overhangs and complex geometries. Choose appropriate infill percentages to balance strength and material usage, adjusting based on the model’s purpose. Lastly, double-check orientation before slicing, as the layout affects print strength and surface finish. Following these steps leads to a smoother printing process and better final products.

3D modeling for printing is revolutionizing the way creators bring their ideas to life. This technology not only enhances creativity but also streamlines the design process, making it accessible to a wider audience. As advancements continue to unfold, the potential applications for 3D modeling will only grow, encouraging innovation across various industries.

By embracing best practices and utilizing the right software, individuals can maximize the benefits of 3D printing. The combination of design flexibility and cost efficiency empowers creators to experiment and refine their projects with ease. As they navigate this exciting landscape, the possibilities for unique and functional designs are truly limitless.