Table of Contents

ToggleIn a world where everything seems to be going digital, 3D metal fabrication is like the superhero of manufacturing. Imagine turning a pile of metal into a finely crafted masterpiece, all thanks to technology that’s more impressive than your uncle’s fishing stories. This innovative process not only saves time but also opens the door to creativity that traditional methods can only dream of.

Overview of 3D Metal Fabrication

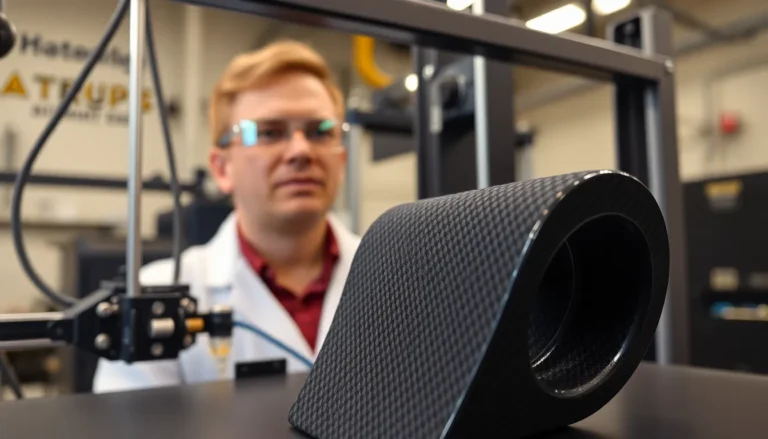

3D metal fabrication represents a significant advancement in manufacturing processes. This technology enables the layer-by-layer addition of metal materials to create complex geometries. Using techniques such as selective laser melting and electron beam melting, manufacturers achieve high precision and detail.

Efficiency increases as 3D metal fabrication allows for rapid prototyping and reduced lead times. Customization becomes more accessible; designers can produce unique components that meet specific requirements without extensive tooling changes. Traditional methods often require molds that limit creativity and flexibility.

Materials for 3D metal fabrication include stainless steel, aluminum, and titanium alloys. Each material offers distinct properties, catering to various industries such as aerospace, automotive, and medical. Characteristics such as strength and corrosion resistance make these materials ideal for advanced applications.

Cost-effectiveness also emerges as a crucial advantage. Reduced waste results from additive processes, addressing environmental concerns tied to manufacturing. As the technology matures, prices for 3D printers and materials continue to decline, making it more feasible for small to medium businesses.

As industries explore new applications, opportunities expand for 3D metal fabrication. Engineers and designers collaborate to push the boundaries of product designs. Innovative uses in sectors like lightweight structures for aerospace and customized medical implants illustrate the versatility of this technology.

Key Technologies in 3D Metal Fabrication

3D metal fabrication relies on several key technologies that enhance precision and efficiency. Two notable methods include Selective Laser Melting and Electron Beam Melting.

Selective Laser Melting (SLM)

Selective Laser Melting employs a high-powered laser to fuse metal powder layers. This method allows for intricate designs and complex geometries that traditional techniques struggle to produce. It offers exceptional density and mechanical properties, making it ideal for aerospace and medical applications. Multiple materials like stainless steel and titanium can be processed, catering to diverse industry needs. The SLM process supports rapid prototyping, enabling designers to test and refine products quickly. Additionally, this technology helps reduce material waste, affirming its sustainability in modern manufacturing practices.

Electron Beam Melting (EBM)

Electron Beam Melting utilizes high-energy electron beams to melt metal powder, laying down layers in a vacuum environment. This technique enhances material properties through better control of heat and energy. EBM is particularly well-suited for titanium alloys, which are widely used in the aerospace and medical fields. The vacuum condition minimizes contamination and oxidation, ensuring high-quality outputs. EBM’s ability to create dense parts reduces the need for extensive post-processing. Speed in producing complex geometries makes it an attractive option for manufacturers looking to innovate and streamline production.

Applications of 3D Metal Fabrication

3D metal fabrication plays a vital role across various industries, offering opportunities for innovation and efficiency. Its impact is particularly significant in the aerospace, medical, and automotive sectors.

Aerospace Industry

In the aerospace industry, 3D metal fabrication enables lightweight structures that enhance fuel efficiency. Components produced through Selective Laser Melting possess exceptional mechanical properties, essential for aircraft performance. Reduced weight translates to lower fuel consumption and improved environmental sustainability. Custom parts, designed specifically for individual aircraft models, streamline production processes. Engineers benefit from rapid prototyping, significantly shortening development cycles and improving design flexibility.

Medical Sector

The medical sector has embraced 3D metal fabrication for creating personalized implants and surgical instruments. Tailored medical devices achieve better patient outcomes through customization that matches individual anatomy. Materials such as titanium alloys ensure biocompatibility and structural integrity. The ability to produce complex geometries supports innovative designs, such as porous implants that promote bone growth. Speedy production processes allow for quick responses to urgent medical needs, enhancing the overall efficiency of healthcare solutions.

Automotive Industry

Within the automotive industry, 3D metal fabrication supports the production of lighter components, which improve vehicle performance and fuel efficiency. Manufacturers utilize this technology to create unique parts that enhance durability and reduce production waste. Techniques like Electron Beam Melting ensure high-density components, resulting in stronger, more reliable vehicles. From rapid prototyping to small-batch production, the adaptability of 3D fabrication meets the evolving demands of the automotive market. Customization enhances innovation, allowing designers to experiment with new concepts in vehicle development.

Advantages of 3D Metal Fabrication

3D metal fabrication offers several advantages that revolutionize manufacturing. First, it enhances design freedom, allowing engineers to create complex geometries without the constraints of traditional methods. Layer-by-layer construction results in intricate designs that were previously unfeasible.

Cost efficiency stands out as another significant benefit. Reduced material waste during the additive process lowers production costs. Industries increasingly adopt this technology due to these savings, making it accessible to small and medium businesses.

Speed is a crucial factor in modern manufacturing, and 3D metal fabrication excels in this area. Rapid prototyping enables quicker testing and iterations of product designs, significantly shortening lead times. This accelerates the path from concept to production.

Customization options grow as well. Tailoring components to specific needs is feasible without the limitations of mold-making. Each piece can reflect unique specifications, providing enhanced functionality across various applications.

Sustainability plays a pivotal role. By focusing on reduced waste and efficient material use, industries can address environmental concerns while maintaining performance quality. This approach aligns with global efforts to promote eco-friendly manufacturing practices.

Finally, the versatility of materials further enhances the advantages. Stainless steel, aluminum, and titanium alloys offer distinct properties that cater to multiple applications, from aerospace to medical. Manufacturers can select the right material based on performance requirements, enhancing overall product efficacy.

Each of these advantages underlines the transformative nature of 3D metal fabrication, providing a competitive edge in an evolving industrial landscape.

Challenges and Limitations

3D metal fabrication faces several challenges that affect its widespread adoption. High costs associated with equipment and materials often limit access, particularly for small businesses. Complexities in the design process can lead to errors, which result in increased time and costs. Variability in part performance can stem from inconsistencies in material quality, affecting the reliability of the final product.

Technical limitations also exist, especially with certain metals. Some alloys may not achieve the desired properties through conventional additive manufacturing processes. The post-processing requirements for 3D printed components can be extensive, necessitating additional time and resources to achieve optimal performance. This adds complexity to the workflow, potentially delaying production schedules.

Regulatory hurdles also present significant barriers. Industries like aerospace and medical must adhere to stringent standards, making compliance difficult and time-consuming. Additionally, the lack of established guidelines for new materials and processes complicates certification efforts.

Knowledge gaps can hinder effective implementation. Many manufacturers don’t fully understand the capabilities or limitations of 3D metal fabrication, which impacts their ability to innovate. Training and education remain necessary for teams to maximize the benefits of this technology.

Market saturation poses another challenge. As more companies adopt 3D metal fabrication, competition increases, which could drive prices down and reduce profit margins. Differentiation among products becomes essential in a crowded market landscape.

Addressing these challenges requires collaboration among engineers, designers, and manufacturers. Solutions may involve investing in research, streamlining processes, and improving training programs, ensuring the growth and viability of 3D metal fabrication in the industry.